Food-grade microalgae production using high-purity CO2 restored from wineries

About MicroAlgae

Vision is to provide a healthy local experience for companies and individuals with healthy, safe, and delicious produce locally grown and benefits the local community and the world.

Mission is to tackle climate change and CO2 emissions in a tangible way and make great use of this CO2 by producing microalgae out of it

Our values are the essence of our identity. At MicroAlgae Production Tech, we are consciously fostering a corporate culture in which our core values are deeply ingrained in our character and serve as a compass to guide our decision-making and business-building processes. They represent our mandates and the source of MicroAlgae Production Tech’s drive and distinctiveness, thoughtfully weaved into our organizational fabric to influence how we think, work, and act.

- Integrity

- Stewardship

- Nurture natural resources

- Innovation

- Dedication

- Respect

Problems We Work On

53,000 tons of CO2 Emissions

Produced by 60M litres of wine/year in Canada.

Food-Grade Microalgae Production

Only organic material can be used for food grade production

Potential Carbon Tax Bill

2019 $20/ton = $218,034 tax

2022 $50/ton = $546,000 tax

Reduction of CO2 Emission

Is one of the major goals of the Paris Agreement to counterbalance the global warming issue.

Carbon Footprint

300K liters of wine/year = 10,920 tons of Co2

17% percent of wine’s carbon footprint is fermentation alone

Solution

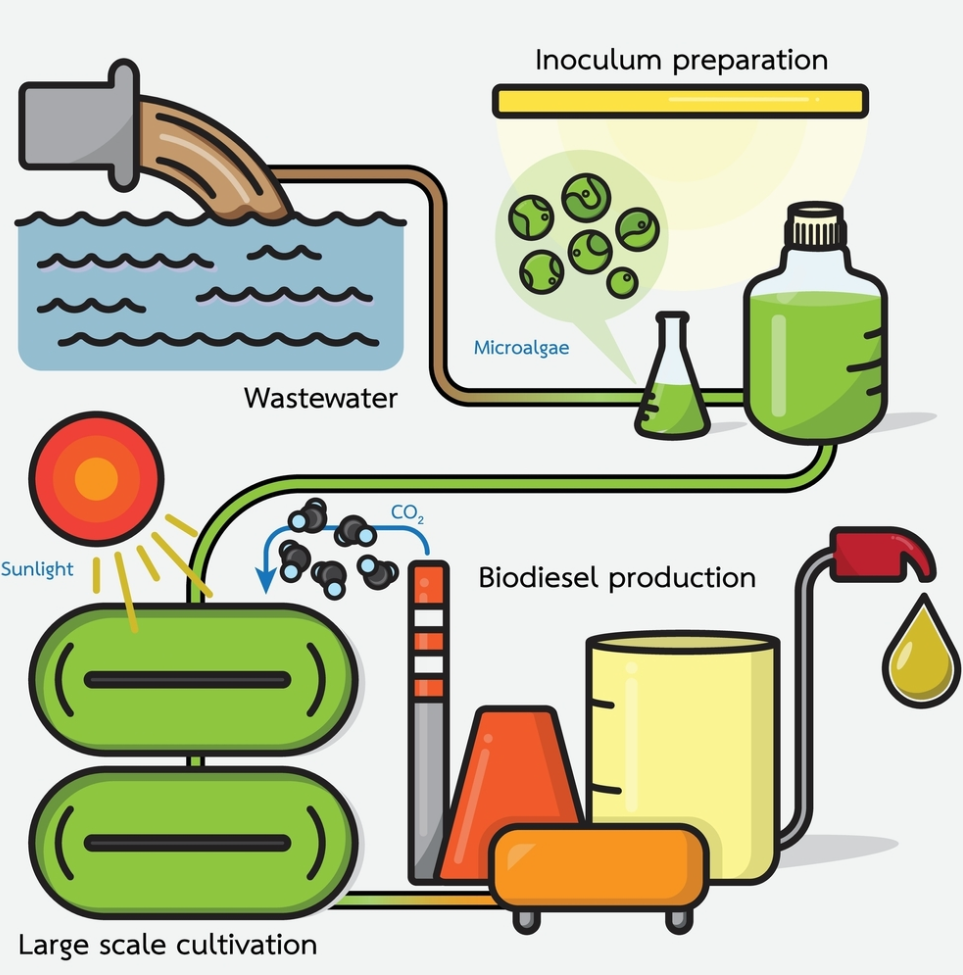

- Re-use the winery CO2 to produce food-grade microalgae

- The stored CO2 from the fermentation process is fed into an engineered tubular photobioreactor for algae production.

- The process allows for endless potential in food & drug applications.

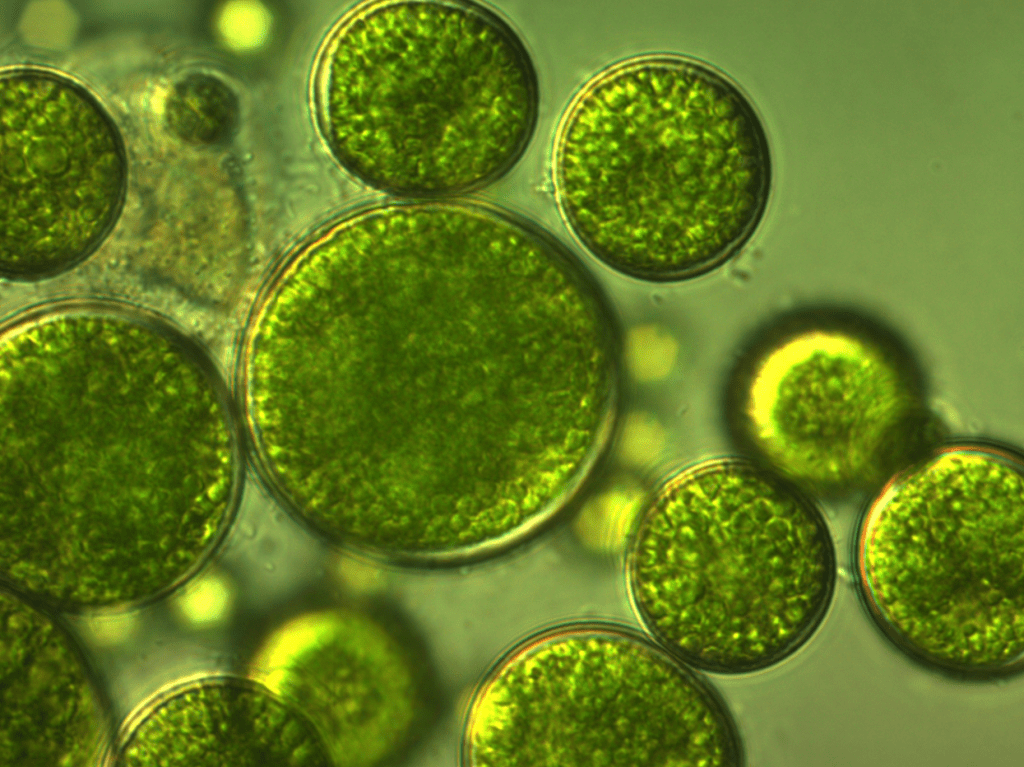

What is Microalgae?

Composed of lipids (7–23%), proteins (6–52%), and carbohydrates (5–23%),

Chemical compositions of microalgae varies over a wide range of factors depending on species and on cultivation conditions.

Microalgae can be used to produce a wide range of metabolites.

Its photosynthetic efficiency is 10 times higher than terrestrial plants, achieving higher growth rates and biomass productivities.

How It Works

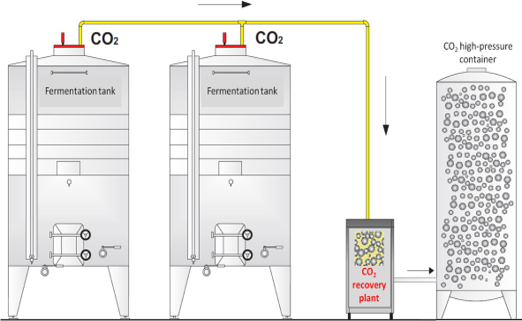

Step 1- Our Carbon Capture

- CO2 collection system

- Directly installed fermentation tanks

- Gas capture through pumps

- Automatic recovery

- Purification through activated carbon filters

- Compressed to 18 bar

- Stored in special high-pressure containers

- Simple distribution system

- Channels the CO2 to the photobioreactors

Step 2- Our Microalgae Cultivation

Carbon Capture Technology

- High grade CO2

- Purity of winery CO2 is very similar to the food-grade CO2 coded as E290.

- Carbon nutrients are 25-30% of microalgae production costs

- Efficient extraction methods save money

- Correct use of fermentation CO2 increases revenue Improves the process eco-sustainability.

Microalgae Cultivation

- Benefits of a closed system

- Less Contamination

- Smaller Footprint

- Less water loss

- Higher Yield

- Tubular photobioreactor is more efficient

Product Demo

Meet Our team

Bamidele Jonathan Olagunju

CEO

He is a successful oil industry entrepreneur with 28 years of experience. He has worked as Site Administrator, Project Coordinator and Entrepreneur. As Chief Executive Officer of MicroAlgae Production Technologies, Mr. Olagunju’s responsibilities includes creating an expansion plan and facilitating the execution of said strategy by working collaboratively with the other executive team members, ensuring that appropriate KPIs are measured, and sales and growth targets are met. He will help to establish and oversee a sales and R&D team.

Ganiyu Olakunle Bello

CCO

He is an intelligent lawyer with 26 years of experience. He has worked as legal counsellor, Associate Partner, Managing Partner and Principal Counsel. As Chief Compliance Officer of MicroAlgae Production Technologies, he aims to utilize his excellent years of experience to bring the company to the Canadian market, expected to be a thriving and profitable business.

Christianah Opeyemi Adegbonmire

COO

She is an enthusiastic, highly communicative Real Estate Entrepreneur with 18 years of experience. She has worked as Management Surveyor and COO. As Chief Operating Officer of MicroAlgae Production Technologies, Mrs. Adegbonmire will be managing daily business operations, in proximity to the heads to ensure smooth running and success in Canada.

Visit Us

Email Us

Info@microalgae.ca