Our product

Solution

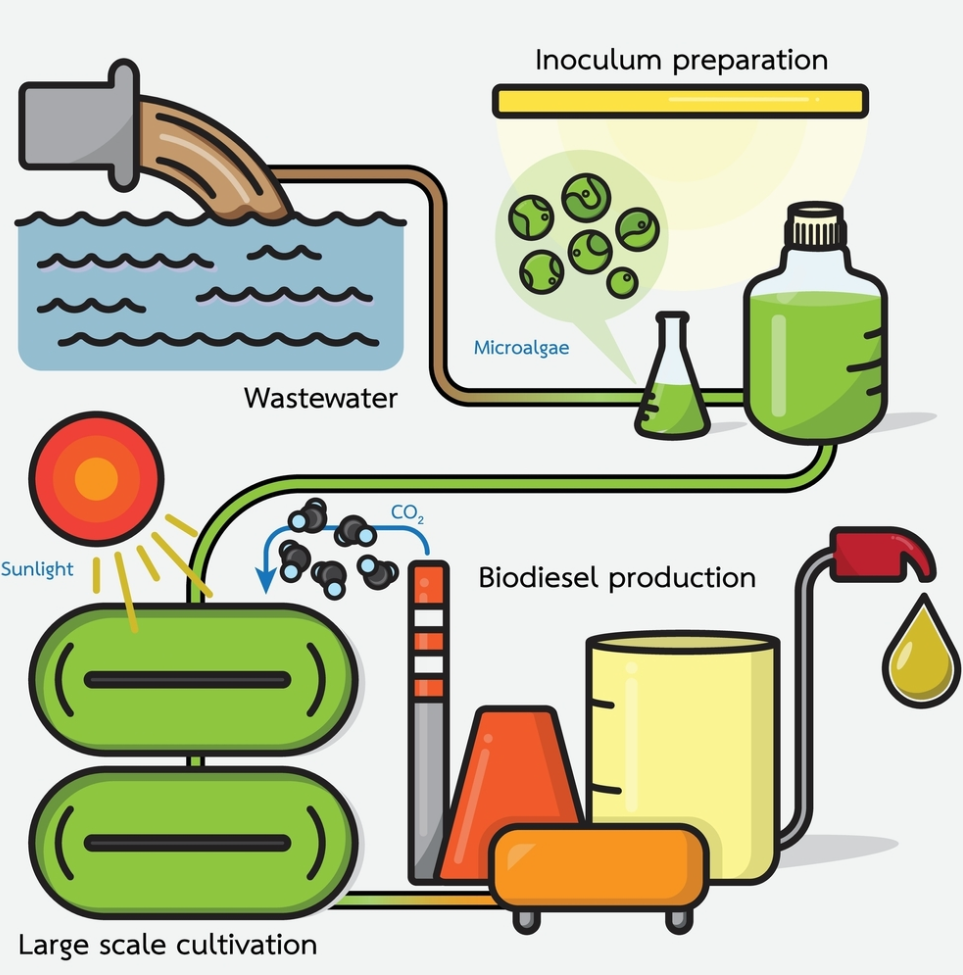

- Re-use the winery CO2 to produce food-grade microalgae

- The stored CO2 from the fermentation process is fed into an engineered tubular photobioreactor for algae production.

- The process allows for endless potential in food & drug applications.

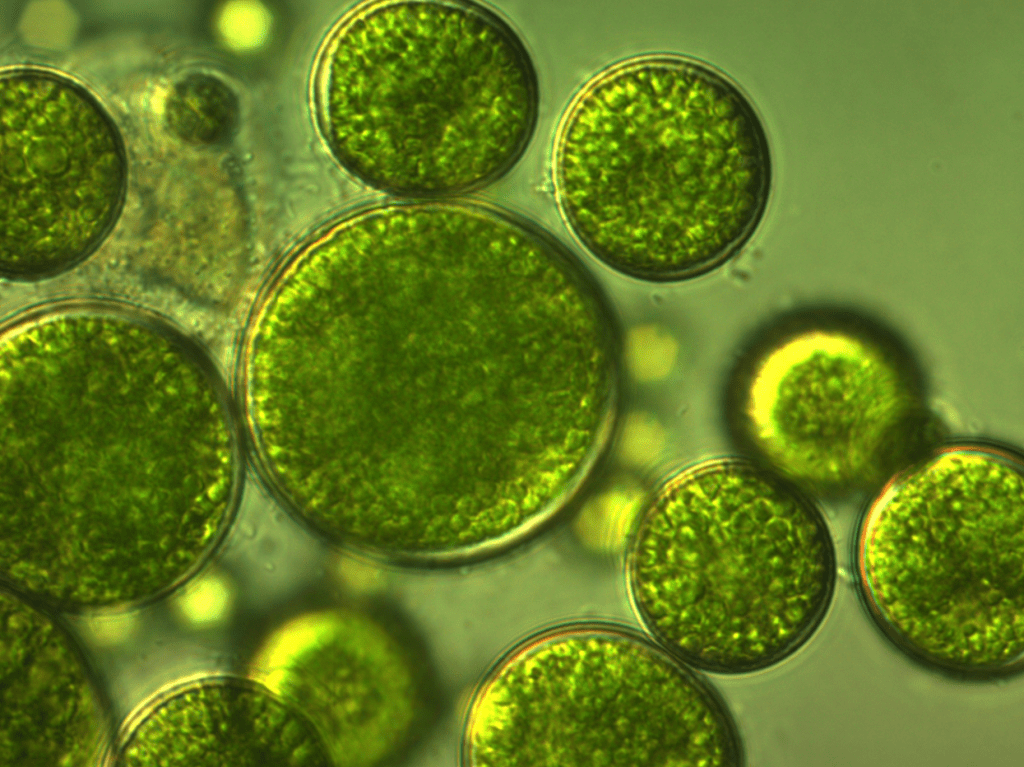

What is Microalgae?

Microalgae are microscopic algae, found in freshwater and marine systems with the size range of 5-100 µm.

Composed of lipids (7–23%), proteins (6–52%), and carbohydrates (5–23%),

Chemical compositions of microalgae varies over a wide range of factors depending on species and on cultivation conditions.

Microalgae can be used to produce a wide range of metabolites.

Its photosynthetic efficiency is 10 times higher than terrestrial plants, achieving higher growth rates and biomass productivities.

How It Works

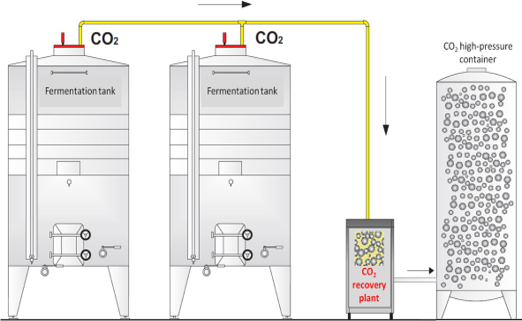

Step 1- Our Carbon Capture

- CO2 collection system

- Directly installed fermentation tanks

- Gas capture through pumps

- Automatic recovery

- Purification through activated carbon filters

- Compressed to 18 bar

- Stored in special high-pressure containers

- Simple distribution system

- Channels the CO2 to the photobioreactors

Step 2- Our Microalgae Cultivation

Carbon Capture Technology

- High grade CO2

- Purity of winery CO2 is very similar to the food-grade CO2 coded as E290.

- Carbon nutrients are 25-30% of microalgae production costs

- Efficient extraction methods save money

- Correct use of fermentation CO2 increases revenue Improves the process eco-sustainability.

Microalgae Cultivation

- Benefits of a closed system

- Less Contamination

- Smaller Footprint

- Less water loss

- Higher Yield

- Tubular photobioreactor is more efficient

Visit Us

205, 10211 Yonge Street, Richmond Hill, ON, Canada L4C 3B3

Email Us

Info@microalgae.ca